Your application is in a potentially explosive atmosphere with limited installation space? That’s no problem with the slim, ATEX-compliant gear units of the F series in a power range from 130 Nm to

Compact and powerful – explosion-proof gear units for limited installation space

Our explosion-proof parallel-shaft helical gear units are assigned to equipment categories II2GD. A wide range of mounting positions and variants enable a broad range of applications. Gas and dust atmospheres are no problem, even under difficult conditions. All that, without having to compromise on the performance. What many of our gear units offer: long service lives without maintenance and wear-free gearing with a high fatigue strength.

With a high torque rating from 130 Nm to 18,000 Nm, our parallel-shaft helical gear units with explosion protection offer great performance in many conveying and processing applications.

You can choose between foot, flange or shaft-mounted options. For precise positioning tasks, our parallel-shaft helical gear units are available with reduced backlash.

Only half the solution without a motor? Then use our sophisticated modular concept and combine the explosion-proof gear units of the F series with the explosion-proof motor of your choice.

Your benefits

-

Low space requirement

due to a slim and compact design. -

Wide range of applications

thanks to 11 frame sizes from type F 27 to type F 157 and numerous variants for very different requirements. -

Always a powerful performance

even in the reduced backlash design with output torques from 200 to 18,000 Nm.

Features

- Gear units comply with Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX), equipment group II, categorie 2, variant II2GD

- For use on the European market

- Accepted in China

- Accepted in Russia in combination with EAC certificates (formerly GOST-R)

- Certified protection types:

- Protection type “c”: Protected by safe construction (design safety), EN13463-1 and -5

- Protection type “k”: Protected by liquid immersion, EN13463-1 and -8

- Standardized robust covers as shrink disk covers on the gear unit

- All screws are secured against automatic loosening

- Gear unit has a separate nameplate

- High-quality oil seals

- Lubricant can withstand high temperatures

- Slim design for limited installation space

- Also available with reduced backlash

- Available variants:

- Foot- or flange-mounted

- B5 or B14 flange-mounted

- Solid or hollow shaft

- Hollow shaft with keyed connection, shrink disk, splined hollow shaft, or TorqLOC®

Technical data

F series / sizes 27 / 37 / 47 / 57 / 67 / 77 / 87 / 97 / 107 / 127 / 157

| Gear unit ratio | i | 3.77 – 281.71 |

|---|---|---|

| Gear unit ratio – double gear units | i | 87 – 31,434 |

| Max. output torque | Nm | 130 – 18,000 |

| Motor power range (Mounting via AM motor adapter) | kW | 0.12 – 200 |

Areas of application

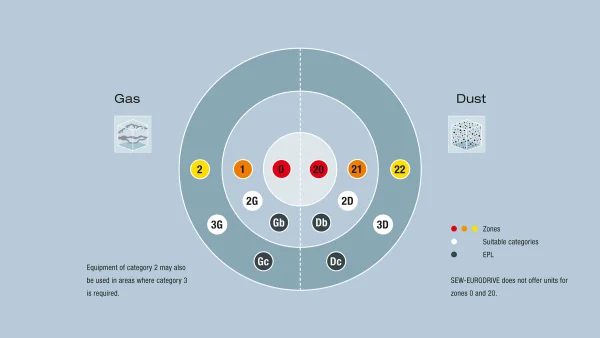

- Applications in potentially explosive atmospheres with air/gas or air/dust mixtures according to Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX)

- Applications with equipment categories II2GD

- Use with air mixtures

- With gases (G): in zones 1 and 2

- With dusts (D): in zones 21 and 22

- Examples:

- Conveyor applications

- Chain conveyors

- Process applications

- Presses

- Extruders

- Screw conveyors

- Gantry cranes