Two-stage helical-worm gearmotors from the S..EDR.. series are particularly cost-effective. The explosion-proof design of these gearmotors can be used in environments classified as zones 1, 2, 21, and 22.

Explosion-proof helical-worm gearmotors for potentially explosive areas

Looking for a reliable, low-maintenance, and explosion-proof drive solution? Then our helical-worm gearmotor from the two-stage S..EDR.. series is the perfect choice for you.

The combination of reliable motor and robust helical-worm gear unit offers you ATEX-compliant protection in medium torque ranges. Thanks to their specific design features, these gearmotors run particularly smoothly and quietly. The two-stage design of the explosion-proof S..EDR.. helical-worm gearmotors provides very high efficiency.

Another benefit of this drive is that it is particularly cost-effective. Thanks to its simple and robust design, you can make significant savings on costs and installation space, giving you the ideal explosion-proof drive solution.

Our S..EDR.. helical-worm gearmotor offers you motor power ratings from 0.12 kW to 45 kW. Depending on the selected drive configuration, you can achieve output torques in the range of 92 Nm to 4000 Nm. Take advantage of all the optional features available, such as flange-mounted or foot-mounted motors, or solid-shaft or hollow-shaft designs.

Your Benefits

-

Safety integrated

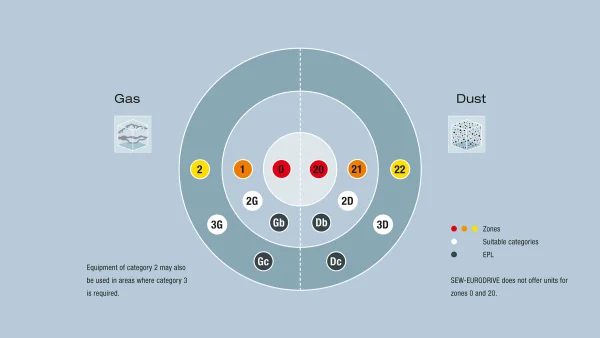

This ATEX-compliant gearmotor fulfills the requirements of equipment categories II2GD and II3GD. -

Smooth operation

The design of the S..EDR.. helical-worm gearmotors ensures particularly smooth, attenuated operation. -

Compact installation

This is made easy thanks to the right-angle-gear-unit design and reduced installation space requirements.

Features

Explosion-proof helical-worm gear unit

S series: two stages

- Gear units comply with Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX), equipment group II, categories 2 and 3

- Certified protection types:

- Protection type “c”: Protected by safe construction (design safety), EN13463-1 and -5

- Protection type “k”: Protected by liquid immersion, EN13463-1 and -8

- Standardized robust covers as shrink disk covers on the gear unit

- All screws are secured against automatic loosening

- Gear unit has a separate nameplate

- High-quality oil seals

- Lubricant can withstand high temperatures

- Significantly more efficient than pure worm gear units due to helical-worm combinations

- Very low-noise operation

- Available versions:

- Foot-mounted or flange-mounted

- B5 or B14 flange-mounted

- Solid or hollow shaft

- Hollow shaft with keyed connection, shrink disk, splined hollow shaft, or TorqLOC

Explosion-proof AC motors

EDR.. series

- Compliant with EC Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX) and IECEx

- Can be used in categories 2G, 2GD and 3GD, 3D for zones 1 / 21 and 2 / 22

- Also available as brakemotor in category 3

- Conform to the efficiency class IE2

- In accordance with IECEx to EPL Gb and Db as well as Gc and Dc

- In accordance with the IECEx Certified Equipment Scheme, EDRS and EDRE motor types are audited and certified by PTB by means of ExTr, QAR, and CoC. For more information on the certification system, see the website of the International Electrotechnical Commission.

- Operation on a frequency inverter, also in field-weakening operation, for categories 2 and 3 and/or EPL .b and .c

- According to HazLoc-NA® (NEC500/C22.1)

- Motors are certified according to the Class Division System and therefore meet the explosion protection requirements for the North American market

- Available as CID2 type, for Division 2 Class I for gas groups A, B, C and D

- Available as CIID2 type, Division 2 Class II for dust groups F and G

- Available as type /CICIID2, for Division 2 Class I for gas groups A, B, C and D and Class II for dust groups F and G

- Also available as brakemotor

- Operation with frequency inverter possible

Technical data

S..EDR.. gearmotors

| S.. gear units (two-stage) | EDR.. motors | ||

|---|---|---|---|

| Gear unit size | MaMax. Gear unit Nm |

Size | Power kW |

| 37 | 92 | 71S4 – 90L4 |

0.12 – 1.5 |

| 47 | 170 | 71S4 – 100LC4 |

0.12 – 3 |

| 57 | 295 | 71S4 – 100LC4 |

0.12 – 3 |

| 67 | 520 | 71S4 – 132M4 |

0.12 – 5.5 |

| 77 | 1270 | 71S4 – 160M4 |

0.12 – 9.2 |

| 87 | 2280 | 71M4 – 180L4 |

0.55 – 18.5 |

| 97 | 4000 | 71M4 – 225M4 |

0.55 – 45 |

Areas of application

- Applications in potentially explosive areas with air/gas or air/dust mixtures according to Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX)

- Applications with equipment categories II2GD and II3GD

- Use with air mixtures

Examples:

- Drives for infrequent speed variations

- Presses

- Rotary tables

- Corner transfer units