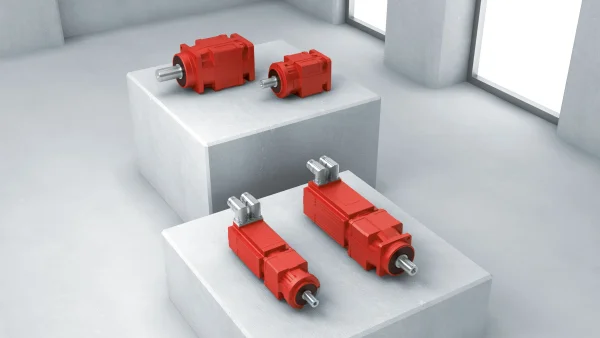

With the compact planetary servo gearmotors of the PS.F.. and PS.C..CMP.. series we offer you precision, optimum scalability and the right torques at all times. This allows complex production processes to be implemented.

Dynamic servo gearmotors for real precision applications

Rely on high power density, dynamics and precision right from the start when designing your systems. As the low backlash planetary servo gearmotors of the PS.F..CMP.. and PS.C.CMP.. series are characterized by tremendous efficiency and flexibility.

The basis is formed by the compact combination of powerful planetary gear units and dynamic synchronous servomotors from the CMP.. series. Planetary servo gear units account for constantly low rotational clearances, high torsional rigidity and torque. The synchronous servomotors of the CMP.. series ensure precise control and high dynamics. This enables you, even with the highest cycle rate requirements, to optimally match different precision sequences to each other and achieve powerful performance.

Thanks to their high degree of efficiency, their reliability and their durability, our planetary servo gearmotors offer you an economically sound solution from the modular system. With endless options and individual implementation possibilities: Always tailor-made, always perfectly and individually configured.

Configure your own product

- Detailed information about your individual product

- CAD data and documentation for your configuration

- Direct order request or ordering

Your benefits

-

Implement power

as the planetary servo gearmotors offer dynamic power delivery in torque classes up to 320 Nm. -

Work with precision

as the accurate scalability and short response times of the planetary servo gearmotors permit exact and complex processes. -

Operate reliably

with proven technology that ensures optimum process sequences and safe implementation.

Features

Low backlash planetary servo gear units

PS.F series

- Low-backlash planetary servo gear units

- Designed for nominal torques from 25 Nm to 3000 Nm

- Available in three output variants:

- PSF: B5 output, flange, smooth solid shaft (without key)

- PSKF: B5 output, flange, solid shaft with key

- PSBF: B5 output, flange block shaft according to EN ISO 94

- Easy mounting of (third-party) motors using the EPH motor adapter

- Life-long lubrication

- Surface protection: OS1 to OS4

- High permitted overhung loads

PS.C series

- Planetary servo gear units

- Designed for nominal torques between 30 Nm and 320 Nm

- Provide the basis for diverse, dynamic, and above all, cost-optimized drive solutions

- Compact, lightweight design

- Any mounting position

- Life-long lubrication

- Surface protection: OS1 to OS4

- Available in four output variants:

- PSC: B5 output, flange, solid shaft

- PSKC: B5 output, flange, solid shaft with key

- PSCZ: B14 output, flange, solid shaft

- PSKCZ: B14 output, flange, solid shaft with key

- Easy mounting of (third-party) motors using the ECH motor adapter

Synchronous servomotor

- Highest dynamic characteristics throughout the entire CMP.. series thanks to the low-inertia rotor design and high overload capacity of the motors

- Performance-optimized and extremely compact design thanks to the latest winding and magnet technology

- Standstill torques from 0.5 Nm to 95 Nm

- Optional CMPZ.. motor variant with increased rotor inertia for all applications with high load moments of inertia

- High quality of concentric running characteristics

- Direct mounting of the motor on a gear unit from our modular gear unit system

Technical data

Planetary servo gearmotors

PS.F series with CMP.. motor

| Gear unit | Motor | ||||

|---|---|---|---|---|---|

| Gear unit type | Gear unit size | Size | Torque range MaDyn Nm |

||

| From | To | From | To | ||

| PS.F | 121 | 40M | 50L | 15 Nm | 38 Nm |

| 122 | 40M | 50L | 26 Nm |

38 Nm |

|

| 221 | 50S | 63M | 15 Nm |

85 Nm |

|

| 222 | 40M | 50L | 60 Nm |

85 Nm |

|

| 321 | 50S | 71M |

21 Nm |

168 Nm |

|

| 322 | 50S | 63M | 82 Nm |

169 Nm |

|

| 521 | 50M | 80L | 51 Nm |

385 Nm |

|

| 522 | 50S | 71M | 82 Nm |

385 Nm |

|

| 621 | 63M | 100L | 150 Nm |

705 Nm |

|

| 622 | 50M | 80L | 250 Nm |

745 Nm |

|

| 721 | 80S | 100L | 290 Nm |

1230 Nm |

|

| 722 |

50M | 80L | 250 Nm |

1540 Nm |

|

| 822 | 63L | 100L | 735 Nm |

2740 Nm |

|

| 922 | 80S | 100L | 1150 Nm | 4200 Nm | |

PS.C series with CMP.. motor

| Gear unit | Motor | ||||

|---|---|---|---|---|---|

| Gear unit type | Gear unit size | Size | Torque range MaDyn Nm |

||

| From |

To |

From | To |

||

| PS.C | 221 |

40M |

63L |

11 Nm |

42 Nm |

| 222 |

40M |

63M |

37 Nm |

42 Nm |

|

| 321 |

50S |

71M |

15 Nm |

91 Nm |

|

| 322 |

50S |

71M |

76 Nm |

91 Nm |

|

| 521 |

50M |

80M |

31 Nm |

220 Nm |

|

| 522 |

50M |

80M |

102 Nm |

220 Nm |

|

| 621 |

63L |

100L |

150 Nm |

425 Nm |

|

| 622 | 63L | 100L | 380 Nm | 425 Nm | |

Areas of application

- Packaging machines

- Machine tools

- Filling and metering units

- Labeling machines

- FFS machines

- Incremental launches

- Pick & place robots

- Robot travel axes

- Flying saw

- Processing machines

- Handling gantries

- Conveyor belts

- Feed, pivoting and auxiliary axes

- Travel axes, additional axes

- Wood processing centers