Our motor starter is generally used in systems which include electronics mounted close to the motor. Besides smooth starting and braking for up to two motors, the innovative unit design offers many benefits for installation operation and service in terms of time and cost.

MOVIFIT® SC for simple handling tasks in decentralized infrastructure

Problem free starting! With our MOVIFIT® SC electronic motor starter. Flexible ramps for starting and stopping. Operation of up to two motors simultaneously or one motor for two directions of rotation. Integrated brake control, which enables operation on virtually all common fieldbus systems with potential decentralized inputs and outputs as well as operation of IE3 motors. Our motor starter offers you a broad areas of applications.

- No startup is necessary with the classic function level. Simple DIP switches make the relevant settings following which the MOVIFIT® SC is immediately ready for use. It is controlled via the PLC using standardized process data profiles. Our "MOVIFIT® Gateway Configurator" provides you with simple configuration and diagnostics options even for more complex applications.

The following also applies for both function levels:

Technology function level

Do you have more individual requirements? Then opt for the technology variant. Here it is all about setting parameters instead of programming. Individually tailored to your application with standardized application modules. Or program freely using the IEC standard language to the PLC open certification standard.

Classic function level

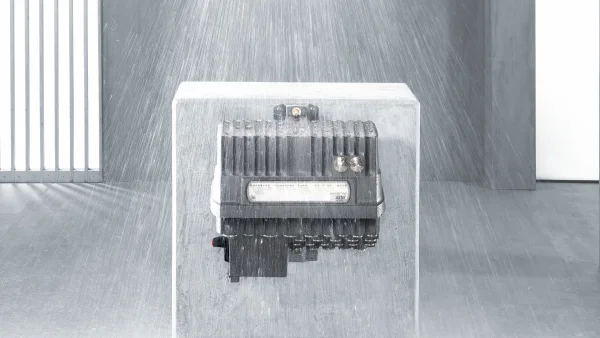

The robust aluminum cast housing in IP65 enclosure protection is divided into electronics unit (EBOX) and connection unit (ABOX). A major benefit is the closing mechanism with only one screw and the automatic unit replacement. This enables quick assembly and smooth unit replacement for servicing.

The integrated T distributor for energy and communication, the integrated repair switch and digital IOs means that a wide variety of external additional components are no longer required for the installation. This saves time and money.

The HygienicPlus design for use in extreme ambient conditions, for example in wet conditions in the beverage industry, is also available as standard.

Configure your individual product

- Detailed information about your individual product

- CAD data and documentation for your configuration

- Option to directly request a quotation or place an order

Your benefits

-

Simple handling

of functions and parameters without additional complexity. -

Low total costs

owing to the operation of IE2 to IE4 motors and savings on external components. -

Rapid system availability

due to pluggable connections, configuration via DIP switches as well as an overall concept with only one screw. -

Individual adaptability

with the technology variant due to free programming with IEC modules.

Features

- Electronic (contactless) motor starter

- Soft start time can be set via parameters

- Integrated brake management

- Increased safety by switching of 3 phases

- Integrated power distribution up to 6 mm2

- Optional maintenance switch

- Comprehensive integrated communication interfaces:

- PROFIBUS® (PROFIsafe optional)

- PROFINET® IO (PROFIsafe optional)

- PROFINET® IO via SC RJ POF

- DeviceNETTM

- EtherNET/IPTM

- Modbus/TCP

- Integrated digital inputs and outputs

- CAN/SBus interface for external components

- Free programming according to IEC 61131

- Integrated parameter memory

- Comprehensive diagnostics via LEDs

- Expanded parameterization and diagnostics via MOVITOOLS® MotionStudio or fieldbus

- Plug-in interfaces for energy, motors (power rating) and IOs

- Robust aluminum housing

- Degree of protection IP65 (IP69K optional)

- Approval: CE, UL and C-Tick

Technical data

- Power range:

- When 2 motors are connected (dual-motor starter): each 0.37 kW to 1.5 kW

- When 1 motor is connected (reversing starter): from 0.37 kW to 3 kW

- Voltage range 3 x 380 V to 500 V / 50 Hz to 60 Hz

- 6 DI + 2 DI/O with classic function level

- 12 DI + 4 DI/O with classic function level and PROFINET fieldbus

- 12 DI + 4 DI/O with technology function level

Connection variants

The motor starter consists of an electronics unit (EBOX) and the connection unit shown here (ABOX). The MOVIFIT® connection box (ABOX) is a large connector and entirely passive. It is available in two designs:

MOVIFIT® standard connection box

MOVIFIT® hybrid connection box

The MOVIFIT® hybrid connection box (ABOX) offers the option of making various connections as a plug. All cables for power supply and the motor cables are routed into the ABOX via cable glands and wired to terminals at this point. M12 connectors are provided for digital inputs and outputs. The bus system can be connected via connectors. The bus connectors vary depending on the fieldbus used.

Function level

The function level indicates the functional scope of the software assigned to the MOVIFIT® units in terms of:

- Software functionality

- Processing the digital inputs and outputs

- Local system control

- Startup operation and diagnostics

Function level overview

| Classic Simple and standardized functions |

|

|---|---|

| Technology Free programming (MOVI‑PLC® / MOVITOOLS® MotionStudio) |

|

Hygienic design

With our HygienicPlus design you will satisfy the demanding hygienic requirements in the food and beverage industry as well as in the chemical and pharmaceutical industry. Upgrade the design of the MOVIFIT® SC, already optimized for use on the field, to gain the optimal requirements for use in the wet area.

- Degree of protection IP69k in accordance with DIN 40050-9 (MOVIFIT® housing closed and all cable bushings sealed according to the relevant degree of protection)

- Easy-to-clean housing (self-draining design)

- Surface with anti-adhering properties

- High impact resistance of the surface against mechanical damage

- Compatibility with cleansing agents having the following properties:

- Alkaline

- Acidic

- Disinfectant

- resistance to temperature fluctuations

- Condensation

- Suction effect (pressure compensation)

Areas of applications

Use of the MOVIFIT® SC motor starter in decentralized plant construction

For integrated field-oriented drive solutions with MOVIFIT®, the focus in the case of the motor starter design is primarily on simple and continuous materials handling applications in the transport, logistics and automobile industry and in the food and beverage industry:

- Pallet conveyors

- Simple skid conveyor technology

- Container and crate transport

- Baggage handling