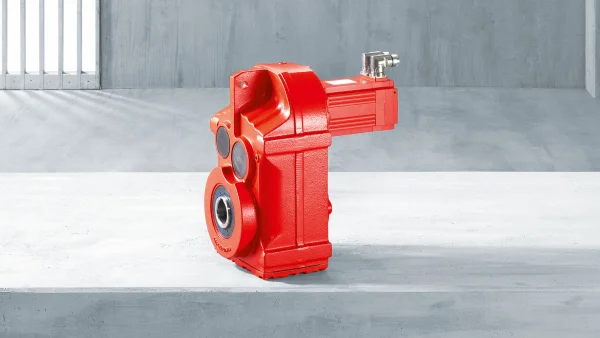

High level of performance and an especially compact design: our F..CMP.. parallel-shaft helical servo gearmotors. They are ideally suited to all of your applications that require precision, dynamics and optimum use of space.

Gearmotor: high power density and maximum power delivery for tight spaces.

A lot of system architecture in materials handling and process engineering is reliant on especially compact drives. We offer you F..CMP.. parallel-shaft helical servo gearmotors for precisely these applications.

The force, dynamics and high precision of this servo gearmotor with a space-saving design are impressive. At the same time, torques of 130 Nm to 7840 Nm can be implemented. Seven sizes from the CMP.. modular motor system are available to you for individually configurable CMP.. servomotors. The parallel-shaft helical gear unit of the F series is optimally designed for precise implementation of complex requirement profiles.

The F..CMP.. parallel-shaft helical servo gearmotors ensure precise performance at all times, adapt perfectly to any system architecture and have a particularly high degree of efficiency.

Configure your individual product

- Detailed information about your individual product

- CAD data and documentation for your configuration

- Direct order request or ordering

Your benefits

-

Drive with minimum space requirements

as the parallel-shaft helical servo gearmotors are designed in such a way that they require minimal space. -

Implement precision

with a highly dynamic and accurately working servo gearmotor for demanding applications. -

Generate power

thanks to a powerful and high torque solution with high efficiency.

Features

Parallel-shaft helical gear units

- Slim design for limited installation space

- Also available with reduced backlash

- Available variants:

- Foot- or flange-mounted

- B5 or B14 flange-mounted

- Solid or hollow shaft

- Hollow shaft with keyed connection, shrink disk, splined hollow shaft, or TorqLOC®

Synchronous servomotor

- Highest dynamic characteristics throughout the entire CMP.. series thanks to the low-inertia rotor design and high overload capacity of the motors

- Performance-optimized and extremely compact design thanks to the latest winding and magnet technology

- Standstill torques from 0.5 Nm to 95 Nm

- Optional CMPZ.. motor variant with increased rotor inertia for all applications with high load moments of inertia

- High quality of concentric running characteristics

- Direct mounting of the motor on a gear unit from our modular gear unit system

Technical data

Parallel-shaft helical-bevel servo gearmotors of the F series with CMP.. motor

| Gear unit | Motor | |

|---|---|---|

| Gear unit size | Size | Torque range MaDyn Nm |

| 27 | 40M – 71M | 15 – 157 |

| 37 | 40M – 71M | 14 – 240 |

| 47 | 40M – 80S | 18 – 435 |

| 57 | 50S – 112S | 26 – 645 |

| 67 | 50S – 112S | 30 – 920 |

| 77 | 63S – 112M | 62 – 1530 |

| 87 | 71S – 112E | 137 – 3090 |

| 97 | 80S – 112E | 275 – 4360 |

| 107 | 80L – 112E | 490 – 8860 |

Areas of application

- Food industry

- Packaging machines

- Packer/unpacker

- Palletizers and packaging machines

- Sorting and stacking systems

- Conveyor belts

- Incremental launches

- Tire, rubber and plastic processing machines

- Travel axes, lifting axes, additional axes

- Positioning drives